Airtac 4V110-06F DC12V Solenoid Valve | 5/2 Way | Compact | Low Power Consumption

Airtac 4V110-06F DC12V Solenoid Valve | 5/2 Way | Compact | Low Power Consumption

Couldn't load pickup availability

1. Core Advantages

The Airtac 4V110-06F DC12V solenoid valve is a compact pneumatic solution tailored for mobile and battery-powered systems. As a low-voltage DC solenoid valve, the DC12V version has extremely low power consumption, maximizing energy savings and extending battery life. Its excellent stability and compact design make it an ideal choice for vehicle-mounted, outdoor, or portable equipment.

2. Product Features

-

Ultra-Low Power Consumption Design: A specially optimized coil structure ensures efficient operation at DC12V, significantly reducing energy consumption.

-

Ideal for Mobile Applications: It's a standard component for mobile pneumatic systems, vehicle-mounted equipment (like bus door controls), and solar-powered systems.

-

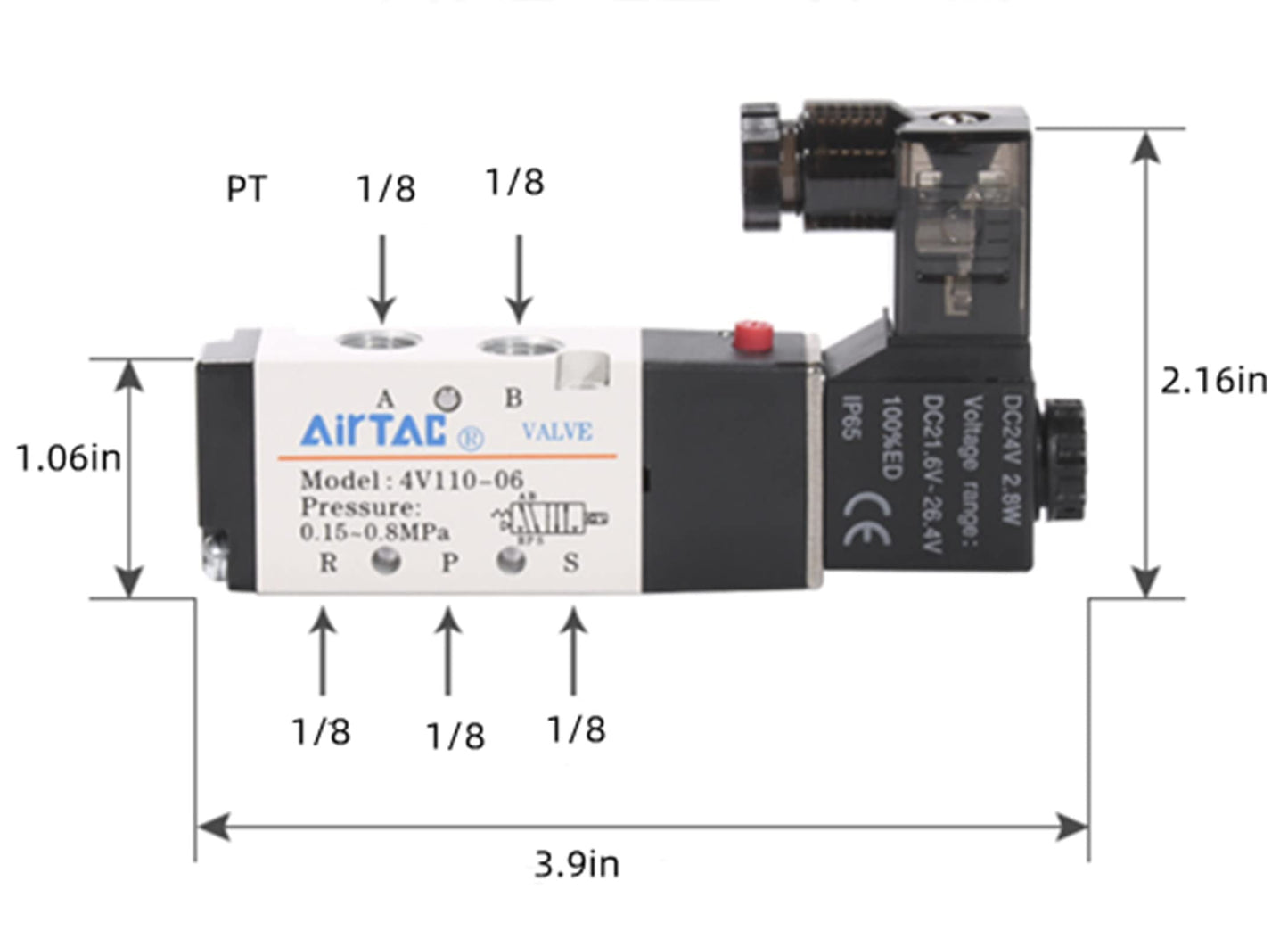

Compact Size, Easy to Integrate: The 1/8-inch port size and compact body design make it easy to integrate into equipment with space limitations.

-

Low Heat & High Safety: Operating on a low DC voltage generates almost no heat and completely eliminates the risk of electric shock, ensuring the safety of both equipment and operators.

3. Technical Specifications

| Parameter | Technical Specification |

| Model | 4V110-06-F |

| Working Medium | 40 micron filtered compressed air |

| Acting Method | Internally piloted |

| Effective Area | 12 mm² (Cv=0.67) |

| Position/Way | 5 Way 2 Position |

| Port Size | P/A/B/R/S: 1/8 inch (PT1/8) |

| Working Pressure | 0.15~0.8 MPa (21.75~116 PSI) |

| Max. Proof Pressure | 1.2 MPa (174 PSI) |

| Operating Temperature | -5 ~ 50℃ |

| Voltage | DC12V |

| Voltage Range | ±10% |

| Power Consumption | 3.0W |

| Protection Class | IP65 |

| Excitation Time | Less than 0.05 seconds |

| Insulation Class | F Class |

| Life | Over 20 million cycles |

Note: For detailed dimension drawings and technical manuals, please contact customer service or download them from our official website.

Physical Dimensions and Installation

To facilitate the integration of our device into your design, we provide precise CAD drawings. [Clear Call-to-Action (CTA)] → [Download CAD Drawings]

FAQs

1. What are the advantages of the DC12V version?

The DC12V version's ultra-low power consumption makes it an ideal choice for battery-powered or vehicle-mounted systems. Its low-voltage operation significantly saves energy, extends battery life, and offers high safety with minimal heat generation.

2. What types of equipment are DC12V solenoid valves typically used in?

Due to its low power consumption and voltage characteristics, the DC12V version is widely applied in vehicle systems (such as bus door control), mobile pneumatic devices, and automation equipment powered by solar or batteries.

3. What is the difference between DC12V and DC24V solenoid valves?

Both are low-voltage DC solenoid valves, with the main difference being the voltage level. DC12V is suitable for 12V power systems, such as car batteries, while DC24V is the industry-standard voltage for PLC control systems. You should choose based on the voltage of your power and control system.

4. How can I tell if a DC12V solenoid valve coil is working properly?

The simplest ways to check are:

-

Listen for a sound: When the coil is powered on, you should hear a crisp "click," indicating the coil has energized.

-

Look at the indicator light: If the solenoid valve has an LED indicator, it will light up when powered on.

-

Measure with a multimeter: Disconnect the power and use a multimeter to measure the resistance across the coil's terminals. If it shows an open circuit or an abnormal resistance value, the coil may be damaged.

5. What should I pay attention to when installing this solenoid valve?

-

Ensure a clean air source: You must use filtered compressed air to prevent impurities from entering the valve body and affecting its operation.

-

Verify the voltage: Before installation, always double-check that the power supply voltage is DC12V to prevent the coil from burning out due to a voltage mismatch.

-

Correct wiring: Strictly follow the wiring diagram on the valve body. Be especially mindful of the polarity of the DC power supply; while it typically doesn't affect function, following the markings is recommended for standardization and easier troubleshooting.

-

Install according to the arrow direction: Strictly follow the airflow direction arrows marked on the valve body during connection to prevent incorrect installation.

Product features

Product features

Materials and care

Materials and care

Merchandising tips

Merchandising tips

Share