Airtac 4V110-06A AC220V Solenoid Valve | 5/2 Way | In Stock

Airtac 4V110-06A AC220V Solenoid Valve | 5/2 Way | In Stock

Couldn't load pickup availability

Meta Description

Buy the Airtac 4V110-06 AC220V solenoid valve, suitable for high-voltage power environments. It offers a fast response and reliable performance. Check prices and technical specifications now!

1. Core Advantages

The Airtac 4V110-06 AC220V solenoid valve is designed for automation systems that connect directly to a 220V AC power source. It simplifies electrical connections by eliminating the need for a transformer while maintaining the compact size of the 4V110 series. Its fast response capability and stable performance make it a reliable choice for pneumatic control in various general industrial machines.

2. Product Features

-

Direct High-Voltage Connection: Ideal for industrial settings like factory workshops that use a direct 220V AC power supply, making wiring convenient.

-

High Response Speed: The AC coil generates powerful magnetic force the moment it is energized, ensuring the spool switches quickly to meet the demands of applications that require a high action frequency.

-

Compact Size, Wide Application: With a 1/8-inch port size and a compact design, it can be used in a variety of small and medium-sized pneumatic control units.

3. Technical Specifications

| Parameter | Technical Specification |

| Model | 4V110-06-A |

| Working Medium | 40 micron filtered compressed air |

| Acting Method | Internally piloted |

| Effective Area | 12 mm² (Cv=0.67) |

| Position/Way | 5 Way 2 Position |

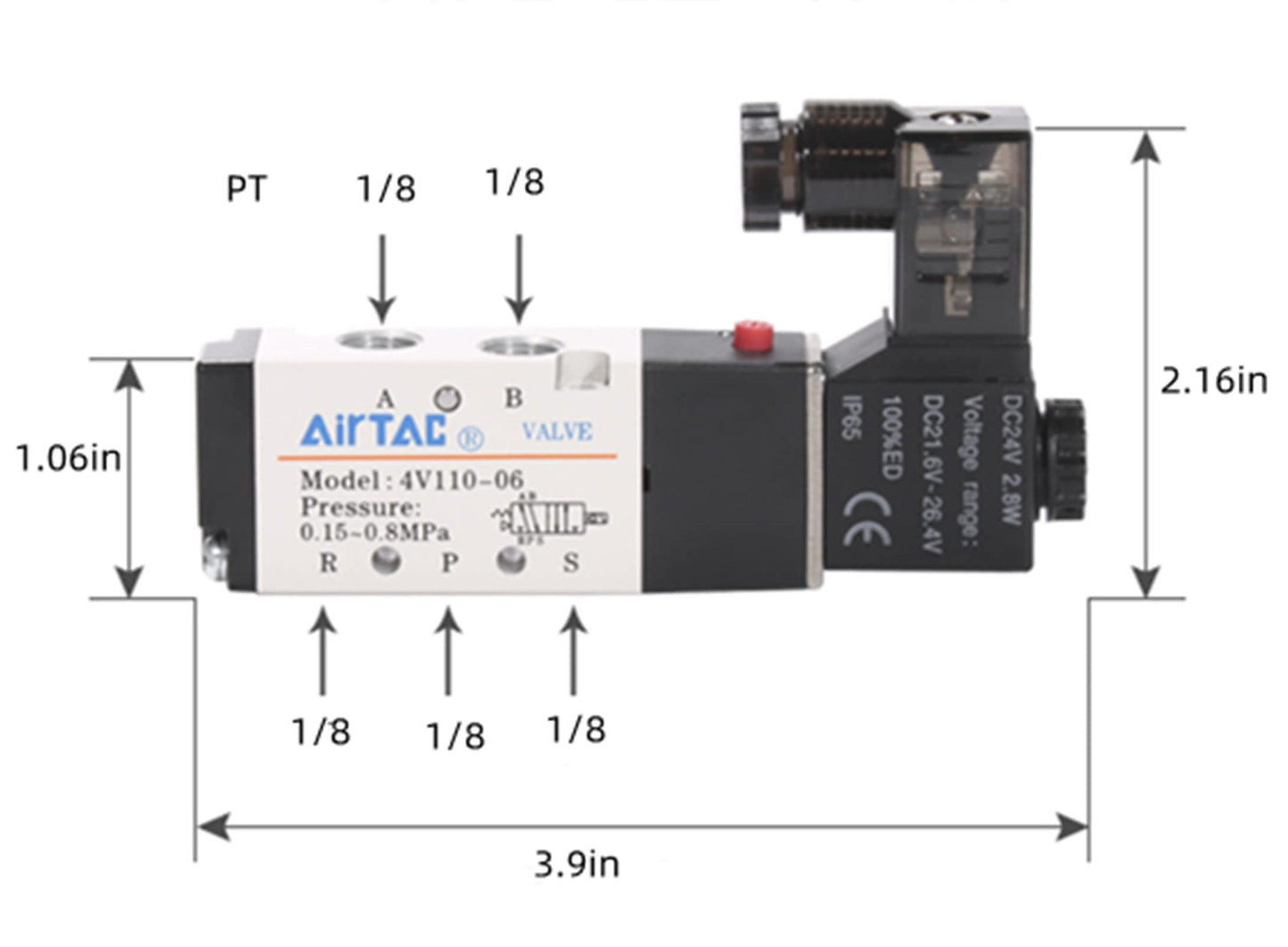

| Port Size | P/A/B/R/S: 1/8 inch (PT1/8) |

| Working Pressure | 0.15~0.8 MPa (21.75~116 PSI) |

| Max. Proof Pressure | 1.2 MPa (174 PSI) |

| Operating Temperature | -5 ~ 50℃ |

| Voltage | AC220V |

| Voltage Range | ±15% |

| Power Consumption | 3.5VA |

| Protection Class | IP65 |

| Excitation Time | Less than 0.05 seconds |

| Insulation Class | F Class |

| Life | Over 20 million cycles |

Note: For detailed dimension drawings and technical manuals, please contact customer service or download them from our official website.

FAQs

1. What are the main application scenarios for the 4V110-06A AC220V solenoid valve?

This solenoid valve is primarily used in industrial equipment that requires a direct connection to a 220V AC power source. It is often found in general-purpose machinery, factory automation equipment, and small production lines where AC220V is the standard power configuration. Using this model simplifies the circuit design and eliminates the need for an additional transformer.

2. Why does the AC220V version's coil make a "humming" sound when powered on?

This is a normal phenomenon and not a malfunction. The nature of alternating current means that the current's direction and magnitude change periodically, causing the magnetic force generated by the coil to pulsate. This pulsating magnetic force causes the coil's iron core to vibrate slightly, which produces the "humming" sound.

3. What are the differences between the AC220V and DC24V solenoid valves?

-

Safety: AC220V is a high voltage, requiring a stronger awareness of safety precautions during installation and maintenance. DC24V, on the other hand, is a safe voltage.

-

Power Consumption and Heat: The power consumption (3.5VA) and heat generation of the AC220V version are slightly higher than those of the DC24V version (3.0W).

-

Application Scenarios: AC220V is often used for high-power and long-distance power supply equipment, while DC24V is the preferred choice for PLC control systems and low-voltage equipment.

-

Noise: The AC version makes a sound during operation, while the DC version is silent.

4. What should I pay special attention to when installing the AC220V solenoid valve?

-

Power-off Operation: You must cut off the power supply before performing any wiring to ensure safety.

-

Correct Wiring: Strictly follow the product's wiring diagram. Note that AC power does not have a positive or negative terminal.

-

Ensure a Clean Air Source: Regardless of the voltage, you must use well-filtered compressed air to extend the solenoid valve's lifespan.

-

Correct Installation Direction: Follow the airflow direction arrows on the valve body during installation.

Product features

Product features

Materials and care

Materials and care

Merchandising tips

Merchandising tips

Share